surface grinding machine parts and functions

A human liver normally weighs approximately 15 kg 33 lb and has a width of about 15 cm 6 in. Parts And Functions of Hydraulic Press Machine Structure Drive System.

Grinding Machine Parts And Functions Mechanical Walkins

A milling machine is a machine tool that cuts metal as the workpiece is fed against a rotating multipoint cutter.

. Here the work piece is fixed on the machine table and the cutting tool is placed on the work piece. Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills grinders routers and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed. It also provides special cycles for complex applications such as interpolation turning and hobbing.

All of this functionality can be programmed with. HiPERFLOOR is available in three distinctive surface finishes. Working Mechanism of Shaping Machine.

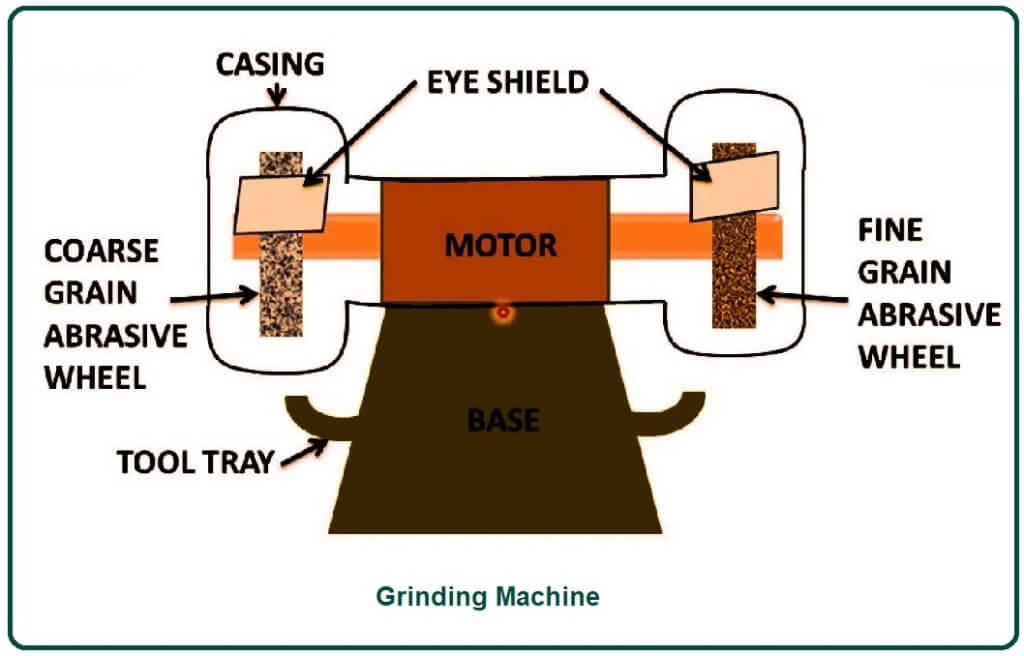

It is composed of coarse-grained abrasive compounds bonded together. The TNC 640 features an extensive package of cycles for milling drilling boring grinding and turning operations. Colour Less used for parting surface.

Different Milling Machine Operations. A grinding wheel is a tool for grinding. The cutting tool is used to give the shape to the hard surface of metal or wood by removing the excess material.

Pump direct drive and pump-accumulator drive. Fig6 Hydraulic press machine drive system. Materials Used for Pattern.

This machine can also hold single or multiple cutters at the same time. Grinding is a commonly used processing method which can obtain higher workpiece density and surface quality. These are some functions of a Pattern.

Some accurate pattern can minimize the production cost of a product because of no further machining is required. Put the steel parts into the inductor make the surface of the steel parts induce current heat to the quenching temperature in a very short time and then spray water to cool. The driving system of hydraulic press mainly consists of two types.

Clients requiring individual machines such as lathes or milling machines or major industrial turn key packages are serviced in exactly the same. The liver is a reddish-brown wedge-shaped organ with two lobes of unequal size and shape. It is used for preparing a mold cavity which is used for Casting any parts.

It is both the heaviest internal organ and the largest gland in the human body. It reduces casting defects. Premium Commercial and Industrial.

The shaping machine operates in the reciprocating type of machine function. By mechanically refining the hardened concrete surface through grinding polishing and chemical treatments a skilled HiPERFLOOR contractor can bring virtually any surface to a whole new level of beauty functionality and strength. Because of the drawbacks with grinding papers alternative fine grinding composite surfaces are available in order to improve and facilitate fine grinding A high material removal rate is obtained by using grain sizes of 15 90 and 60 µm.

After forming a solid round object grinding and abrasive processing can be performed on a grinding machine. The milling cutter rotates at a very high speed because of the multiple cutting edges it cuts the metal at a very fast rate. Since being established in 1951 RK International Machine Tools Ltd a privately owned company spanning three generations have been involved in the supply of quality new and used machine tools.

Located in the right upper quadrant of the abdominal cavity it rests just below the diaphragm to the right of the. To improve the appearance hardness wear resistance and fatigue strength of steel parts and adhere to the endurance of the heart. The pump of this drive system provides high pressure working liquid to the hydraulic cylinder.

Each grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. A grinding machine often shortened to grinder is one of the power tools or machine tools used for grinding it is a type of machining using an abrasive wheel as the cutting tool. Fine grinding produces a surface with little deformation that can easily be removed during polishing.

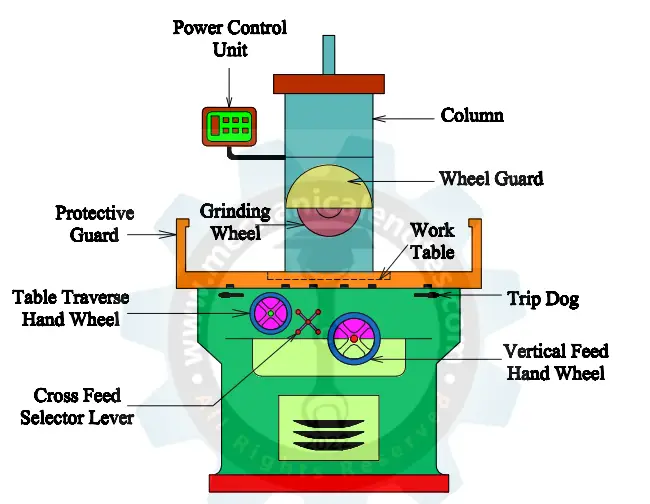

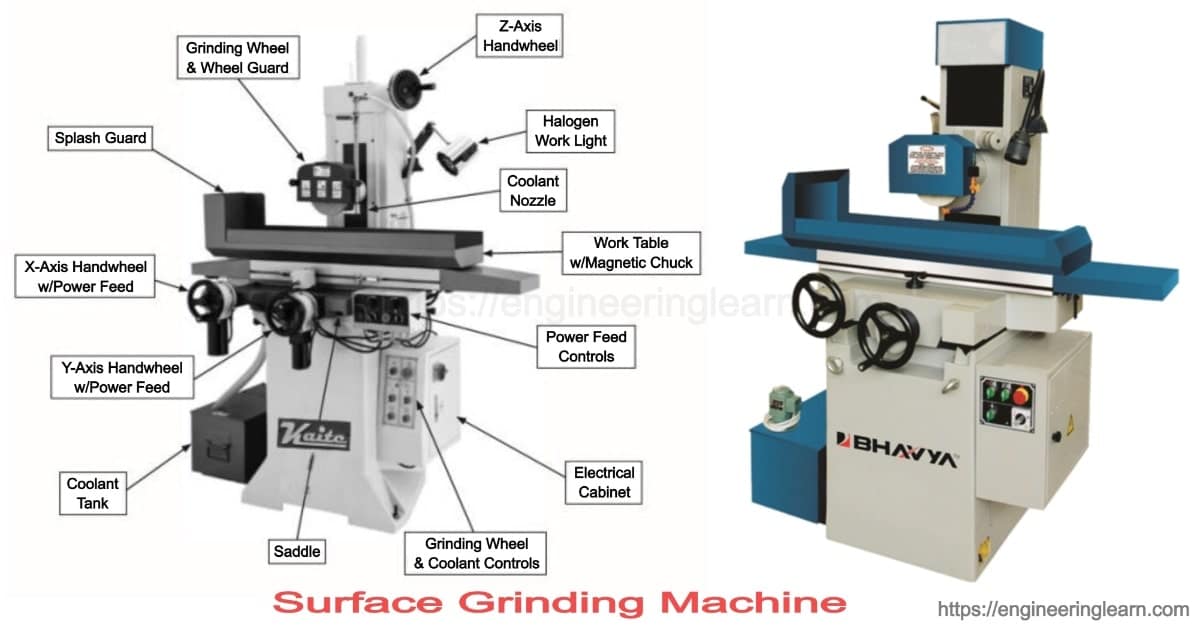

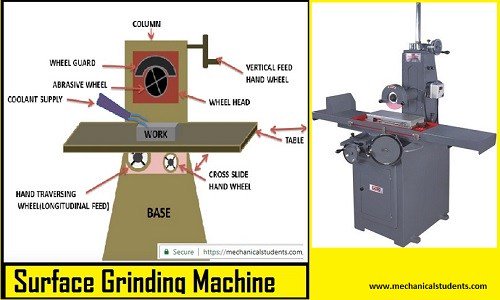

Main Parts And Functions Of Surface Grinder M7140

Surface Grinding Machine In Hindi Youtube

Everything You Need To Know About A Grinding Machine Studentlesson

14 Types Of Grinding Machines Working Diagram Pdf

Types Of Grinding Machines Cad Cam Engineering Worldwide

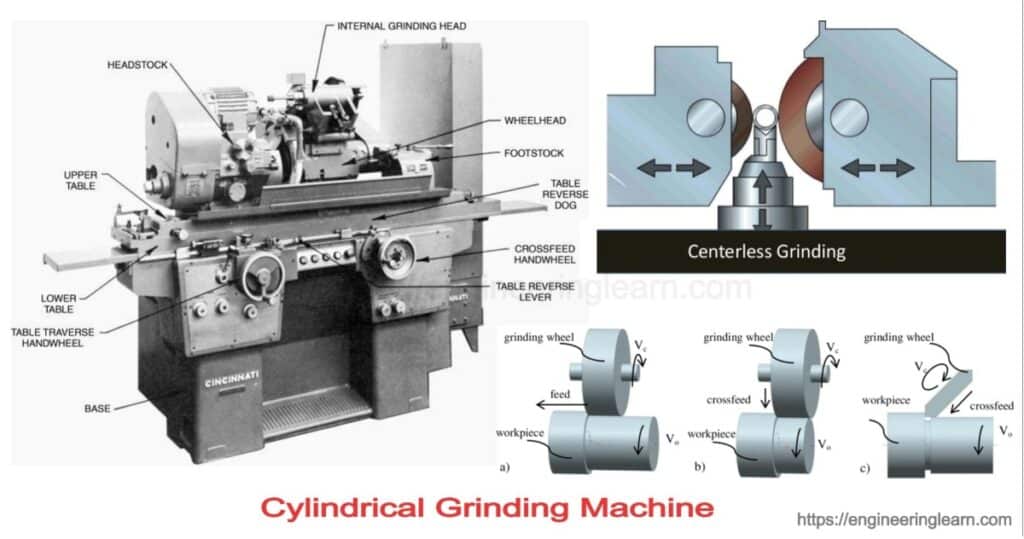

Cylindrical Grinding Machine Types Process Working Principle Engineering Learn

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

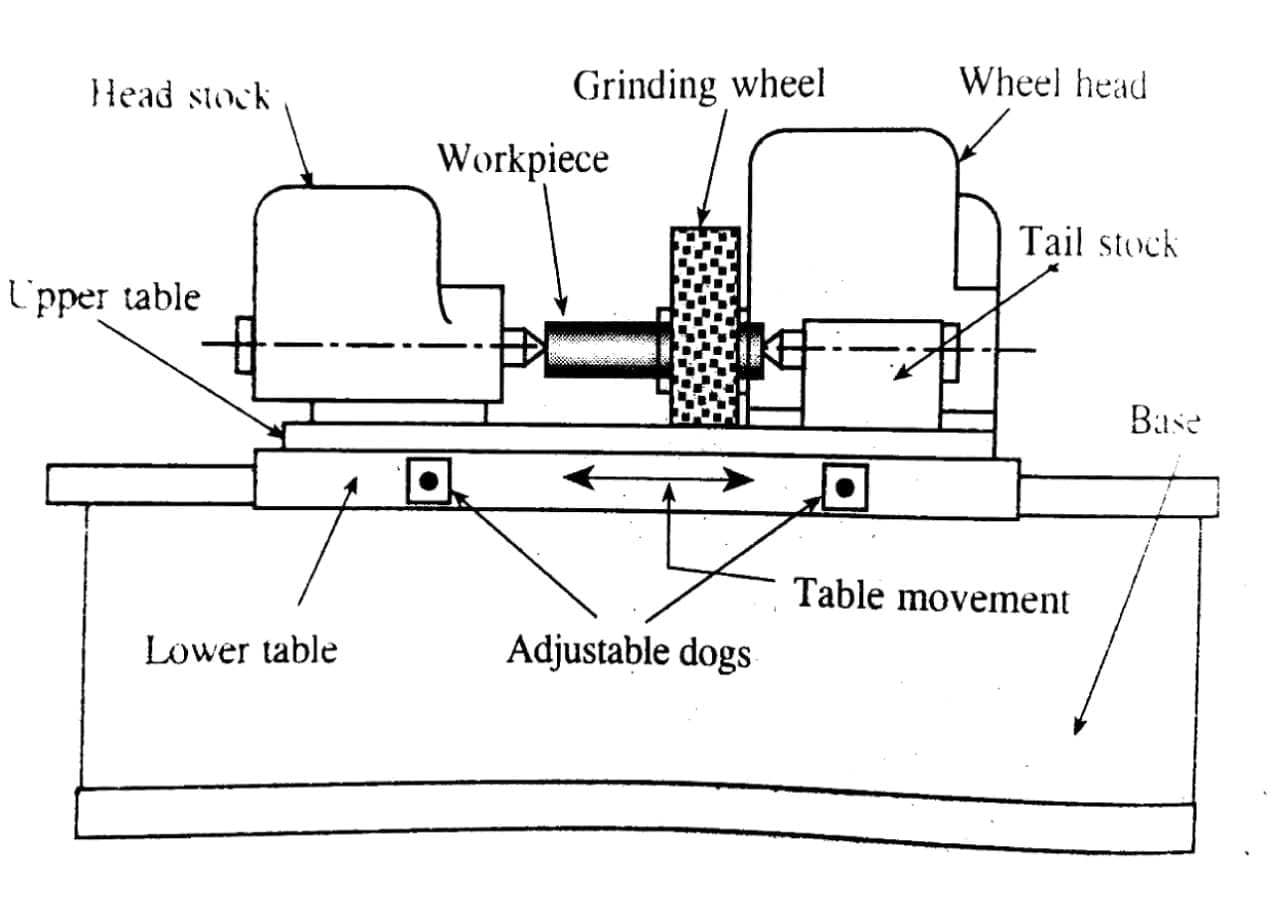

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Surface Grinding Machine Types Parts Working Procedure Engineering Learn

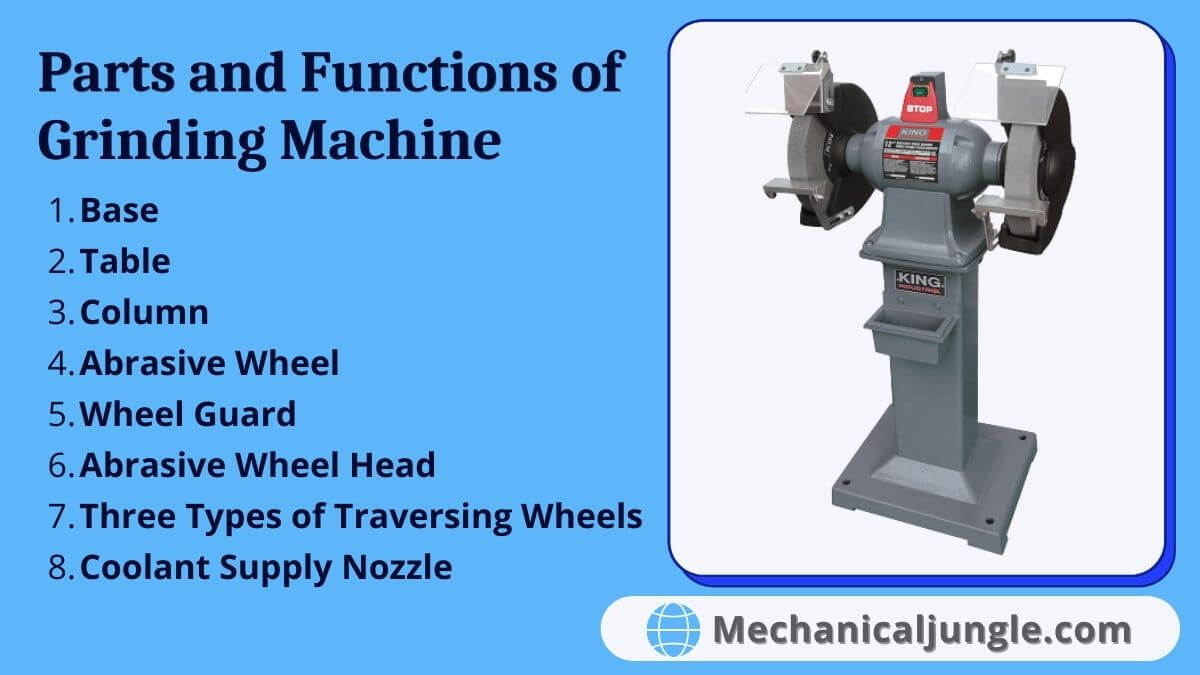

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

Twitter 上的 Mechanical Students Community Surface Grinding Machine Definition Types Of Grinding Process Function Of Parts Working Https T Co B150x9jfis Https T Co Bgna2wk27k Twitter

How To Use A Surface Grinder Machine

Cylindrical Grinding Machine Working Parts Types Uses

Identifying Machine Parts And Their Functions Cad Cam Engineering Worldwide

Everything You Need To Know About A Grinding Machine Studentlesson